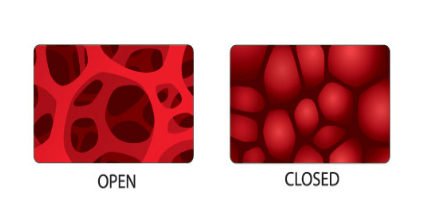

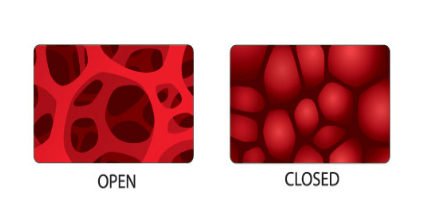

Porous plastic foam is on the cutting edge of insulation for heat, vapor, noise, and other elements. The two major variants of porous plastic foams are open and closed cell foams. Both types of foam are used in everyday products, but because of their structural differences, one type of foam may perform better than the other depending on the desired application.

Foam is created by dissolving gas under high pressure into a polymer while it is in a liquid state, causing the formation of thousands of tiny bubbles, or cells, in the polymer. Each foam has a distinct structure and permeability and performs differently depending on the application. The main difference that cause manufacturers to choose between open and closed cell materials are their permeability to different elements—meaning how effective they are as barriers.

Want to visualize the comparison between open cell and closed cell foam? Jump to the infographic at the bottom of this article: Open vs. Closed Cell Foam.

What is closed cell foam?

In closed cell foam, the cells are like tiny air pockets piled together in a compact configuration, resembling inflated balloons nestled tightly together. Due to the closely packed cells, closed cell foam is vapor semi-impermeable, more rigid, able to withstand greater pressure, and is about 4 times denser than open cell foam.

In closed cell foam, the cells are like tiny air pockets piled together in a compact configuration, resembling inflated balloons nestled tightly together. Due to the closely packed cells, closed cell foam is vapor semi-impermeable, more rigid, able to withstand greater pressure, and is about 4 times denser than open cell foam.

What is open cell foam?

Created using a similar process as closed cell foam, open cell foam is designated to be vapor semi-permeable as the formation of the cells in the material are broken, rather than closed. Similar to the holes inside a sponge, air can permeate the open cells more easily, making open cell foam more porous and absorbent than closed cell foam.

Is closed cell foam air impermeable?

Closed cell foam is a better air barrier than open cell foam, and can be used to control airflow as it is less permeable. For example, closed cell foam could be an effective gasket or seal for climate-control by keeping hot outside air from entering an air conditioned enclosure. Open cell foam is more effective for filtration than closed cell foam because it allows air to pass through it. For instance, open cell foam makes a suitable air filter for an engine because it can capture dust and pollutants but not restrict air flow.

Is closed cell foam waterproof?

When it comes to preventing water vapor from passing through, closed cell is more useful than open cell foam. Closed cell foam is more impermeable to water, vapor, and air. Therefore, it is less likely to be structurally impacted by the effects associated with water damage: mold, mildew, rot, and bacteria.

Does open cell foam absorb water?

Open cell foam has a higher possibility of absorbing water than closed cell foam, which can lead to degraded performance, especially for thermal applications. While engineers do not necessarily strive for perfect vapor impermeability, the free flow of water can be detrimental to a structure and can trap water.

If the environment is moist, closed cell foam might be the better option to work with as it’s less likely to absorb water and become an ineffective insulator. For example, closed cell foam would be better suited for wrapping a water tank than open cell foam.

Open vs. closed cell foam for heat insulation

Both open and closed cell foam are efficient thermal insulators. Depending on the application and environmental factors, however, one type of foam might perform better than the other, especially if the environment is moist. For example, open cell foam might not perform optimally for thermal applications in moist or humid environments: a wet sponge will not retain or deflect heat effectively as water is a poor insulator in comparison to air.

Both open and closed cell foam are efficient thermal insulators. Depending on the application and environmental factors, however, one type of foam might perform better than the other, especially if the environment is moist. For example, open cell foam might not perform optimally for thermal applications in moist or humid environments: a wet sponge will not retain or deflect heat effectively as water is a poor insulator in comparison to air.

Is closed cell foam good for soundproofing?

Open cell foam performs better at absorbing and reducing sound than closed cell foam due to its permeability. The open cell structure allows sound waves to interact with residual membranes so that the energy is transformed into heat, absorbing some of the sound.

What is the cost difference between closed cell and open cell foam?

Open cell foam is considerably more economical than closed cell foam. It is less expensive to achieve the same thermal insulation from open cell foam because it uses less plastic to make, and the air within the open cell foam is an effective insulator.

When selecting a material, cost is often a factor that impacts the decision of engineers and manufacturers just as much as the properties of a particular foam.

Choosing the right type of foam for your manufacturing application

In a broad sense, closed cell foam is semi-impermeable and restricts the flow of air and is less water absorbent, while open cell foam is semi-permeable and allows air and water to pass through it. Depending on your situation, one may be a more effective barrier than the other. If you are having difficulty finding the right kind of the porous plastic foam for your application, consult an expert from Polymer Technologies to assist you.

Open vs. Closed Cell Foam Comparison Infographic