Hydrogen fuel cells offer new opportunities for sustainable energy. They are considered the most energy-efficient devices for extracting power from fuel, capable of having twice the efficiency of traditional combustion technologies. They are also a clean energy source because a bit of water and sometimes heat are the only byproducts of the electrochemical process in fuel cells that directly convert the chemical energy of hydrogen into electricity.

Hydrogen fuel cells are increasingly used in mass transportation, personal vehicles, backup power generation applications, and power for remote locations. However, cost, infrastructure, and durability are among the issues that impact the global adoption of this promising technology, making continued advancements in technology and materials crucial.

We will explore some of the latest advancements in improving the cost-effectiveness, availability, performance, and durability of hydrogen fuel cells and explain how advanced polymers can support versatility and safety in various applications.

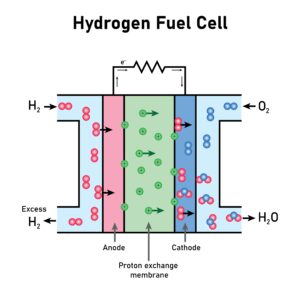

How Do Hydrogen Fuel Cells Work?

A hydrogen fuel cell’s core components include the anode, cathode, and electrolyte. Hydrogen flows through the anode, where a catalyst causes its molecules to split into protons and electrons. The protons pass through the electrolyte membrane while the electrons follow an external circuit to the cathode, generating electricity. Oxygen molecules flow into the cathode on the other side of the fuel cell, which are then combined with the flowing electrons and protons that pass through the membrane to produce water and heat, which is released into the air as vapor.

While the process is seemingly straightforward, hydrogen fuel cells can be prohibitively expensive for some of the materials required for catalysts and structural components. Durability issues stemming from high temperatures and overheating, corrosion, vibrations, and pressure can all lead to material degradation and reduced performance.

Technology Advancements in Energy Efficiency, Storage, and Delivery

New advancements in hydrogen fuel cell technology have helped offset these challenges in durability and increased efficiency and cost-effectiveness. For example, the U.S. Department of Energy’s Hydrogen and Fuel Cell Technologies Office (HFTO) has noted in progress reports how enhanced catalyst materials have improved energy conversion efficiencies.

Specific platinum-group-metal-free catalysts have improved performance by approximately 60% over the 2021 baseline. Researchers are exploring new materials for catalysts that are more abundant for cost-effectiveness and will increase energy efficiency even further. The latest developments in proton exchange membranes (PEMs) and other sophisticated membranes have also helped improve energy efficiency.

According to the HFTO, additional advancements in hydrogen fuel cell technology have addressed cost, storage, and delivery. Innovations in manufacturing processes and material usage have made hydrogen fuel cells more affordable for commercial and consumer applications.

- R&D advancements have reduced the cost of electrolyzers by over 90% since 2001 and 80% since 2005.

- Technology advancements have enabled the projected costs of hydrogen production, delivery, and dispensing to be cost-competitive with gasoline.

- Improved design, materials, and assemblies have lowered the high-volume costs of heavy-duty transportation fuel cells, achieving ~ a 10% reduction from the 2021 baseline.

- Storage innovations have reduced the cost of advanced compressed onboard hydrogen storage systems by 30% since 2013.

- Researchers began producing the nation’s first electrolyzer directly coupled with nuclear power, which will help reduce the production costs of clean hydrogen.

- Hydrogen and fuel cell delivery trucks are now being deployed. These trucks have driving ranges, payloads, and fueling times that are competitive with those of incumbent technologies.

- R&D programs continually explore new ways to optimize cell design to maximize performance, durability, and safety, including implementing advanced polymers.

Increasing Fuel Cell Durability with Advanced Polymers

Hydrogen fuel cells often operate in demanding conditions that could impact their performance and longevity. Manufacturers must consider high temperatures, corrosive materials, and vibrations in their cell design. As a leading developer of thermal, vibration damping, and air and fluid transfer solutions, Polymer Technologies can support many hydrogen fuel cell applications to mitigate these challenges and strengthen cell durability and safety.

Our products for hydrogen fuel cell systems are developed from advanced polymers designed to prevent issues that weaken the cell over time and reduce its efficiency and performance. The following solutions can be custom-engineered to meet manufacturer specifications for temperature, pressure, air and fluid distribution, and more.

Silicone Hoses

Our high-performance silicone hoses are designed to withstand extreme temperatures up to 510℉. Developed from advanced polymers (Silicone, Fluorosilicone, and Fluoroelastomers), they are used for various fluid transfer applications, including cooling systems, emissions, and fuel delivery in hydrogen fuel cells. They are also resistant to degradation and corrosion.

We can work with manufacturers that require an advanced solution to prevent overheating, reduce mechanical stress, or eliminate leaks. Our silicone hoses offer greater flexibility, resilience, and durability to enhance the durability and performance of hydrogen fuel cell systems.

Molded Foam

Our Polymer Molded Products Division (PMP) is a full-service molded polyurethane foam manufacturer with in-house capabilities to push the boundaries of molded product manufacturing. We incorporate advanced polymers in our molded foam development to provide insulation and cushioning to maintain the stability and performance of various hydrogen fuel cell systems. POLYFORM®, for example, is a polyurethane product we developed that can be molded into unique shapes for energy management and crash protection in fuel cells

Our custom-molded polyurethane foam solutions can be used for battery cushions, cover insulation, shields, gap closeouts, and other compartment components for thermal protection, acoustic insulation, and vibration damping.

We also have developed melamine foam products for hydrogen fuel cell systems that require fire protection and exceptional resistance to heat, low flame propagation, and smoke. Melamine is extremely lightweight while still reducing mechanical stress and offering structural support. It also provides excellent acoustic and thermal insulation to manage noise and temperature fluctuations.

As hydrogen fuel cells become more advanced to tackle our biggest energy challenges, future developments in polymer materials will be needed to reduce costs, increase efficiency, and strengthen durability. From polyurethane to melamine and silicone, we will continue to design and develop products with advanced polymers that break the mold and support the evolution of hydrogen fuel cells.

Contact us today to explore our flexible materials for hydrogen fuel cells and discuss how we can accommodate your requirements.