When it comes to insulation solutions for HVAC, power generation, and mass transit, efficiency, safety, and ease of installation are top priorities. POLYDAMP® Melamine Foam (PMF) is a trusted insulation material known for its lightweight composition, excellent thermal and acoustical properties, and compliance with rigorous industry standards. With the adhesive-backed PMF that Polymer Technologies has offered for over three decades, installation becomes even more streamlined, helping manufacturers’ assembly teams save time while improving performance.

When it comes to insulation solutions for HVAC, power generation, and mass transit, efficiency, safety, and ease of installation are top priorities. POLYDAMP® Melamine Foam (PMF) is a trusted insulation material known for its lightweight composition, excellent thermal and acoustical properties, and compliance with rigorous industry standards. With the adhesive-backed PMF that Polymer Technologies has offered for over three decades, installation becomes even more streamlined, helping manufacturers’ assembly teams save time while improving performance.

The Advantages of POLYDAMP® Melamine Foam

PMF is engineered to meet the demanding environments of HVAC, power generation systems, and mass transit vehicles. Key benefits include:

- Extremely Lightweight: With a density of just 0.56 lbs/ft³, PMF helps reduce overall weight, a critical factor in aviation and transportation industries.Exceptional Heat Resistance: It withstands temperatures from -300°F to +356°F continuously and up to +492°F intermittently.

- Superior Flame, Smoke, and Toxicity (FST) Performance: Meeting UL94 V-0 and other industry safety standards, PMF enhances passenger and equipment safety.

- Vibration and Compression Resistance: PMF maintains its performance under mechanical stress, ensuring long-term durability.

- Versatile Applications: From HVAC and ECS ducts to wall and enclosure insulation, PMF is widely used in HVAC, power generation systems, and mass transit vehicles.

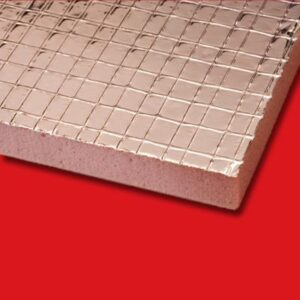

The Game-Changer: Adhesive-Backed PMF

Traditional insulation materials often require mechanical fasteners or spray adhesives, which can be labor-intensive and time-consuming to apply. Adhesive-backed PMF simplifies installation by providing a ready-to-apply solution.

4 Major Benefits of Adhesive-Backed PMF:

- Faster Installation – Pre-applied pressure-sensitive adhesives (PSAs) eliminate the need for separate adhesives, reducing installation time and labor costs.

- Stronger Bonding – High-quality PSAs ensure secure attachment to surfaces, even in high-vibration environments.

- Improved Safety – Reducing the use of mechanical fasteners minimizes potential structural penetrations, preserving the integrity of fuselages, ducts, and enclosures.

- Versatility in Application – Adhesive-backed PMF can be applied to complex surfaces, making it ideal for challenging installations in tight spaces.

Industry Applications

HVAC Systems

Proper thermal and acoustic insulation is crucial for HVAC equipment to enhance efficiency and reduce noise. Adhesive-backed PMF materials provide a secure, hassle-free solution for insulating ductwork, air handlers, and enclosures. Their high-temperature resistance and strong adhesion help improve system performance while minimizing energy loss and unwanted vibrations.

Power Generation Systems

Efficient insulation is essential for thermal management in power generation equipment. PMF’s high-temperature resistance makes it an ideal solution for insulating turbines, ducts, and enclosures, while the adhesive backing ensures a secure fit without additional adhesives or fasteners.

Mass Transit Vehicles

Passenger comfort and noise reduction are critical in mass transportation vehicles like trains, buses, and subway systems. Adhesive-backed PMF helps control heat and noise levels by providing an effective insulation barrier in walls, ceilings, HVAC systems, and engine enclosures.

Streamlining Insulation Installation

For industries where efficiency, safety, and performance matter most, adhesive-backed POLYDAMP® Melamine Foam (PMF) is a game-changer. By eliminating the need for separate adhesives and mechanical fasteners, this innovative solution makes installation quicker, easier, and more reliable. Whether in HVAC, power generation, or mass transit, adhesive-backed PMF helps manufacturers and engineers meet their insulation needs with minimal effort and maximum effectiveness.

Looking for a lightweight, high-performance insulation solution that simplifies installation? Contact Polymer Technologies today to learn more about how adhesive-backed PMF can benefit your application.