Here at Polymer Technologies, we have a team of engineers who are experts in vibration and shock isolation and are ready to answer any questions you have about isolation techniques. No matter your application, we are confident we can create a custom vibration isolation solution that meets your needs and solves your problems. To better help you understand the complex world of isolation and the different types of vibration isolation options available to you, we have outlined the two basic methods below.

Passive Vibration Isolation

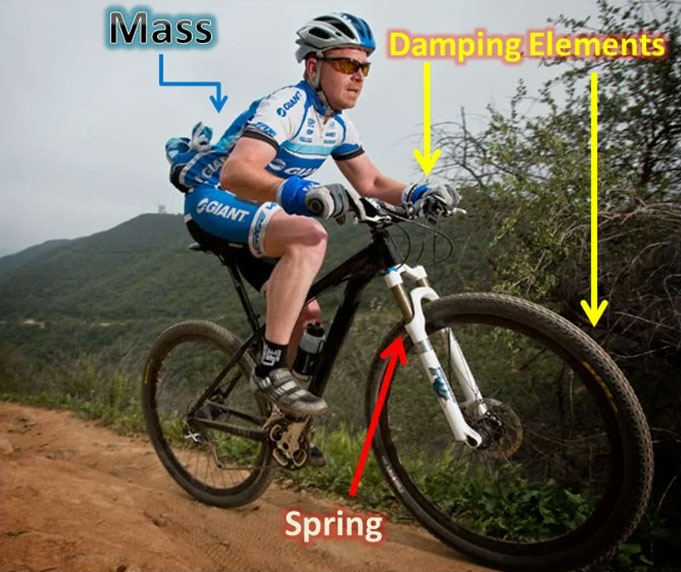

Passive vibration isolation refers to shock mitigation by passive techniques, such as mechanical springs or rubber pads that are mounted to an object that vibrates. Here’s a great example of passive isolation that almost everyone can understand – when riding a bicycle, vibrations from the tires pass through the bicycle wheels to the handlebars, causing your arms and hands to vibrate and shake. Cushioned cycling gloves tend to “isolate” your hands from the handlebars, preventing your hands and arms from getting injured or damaged.

Passive vibration isolation refers to shock mitigation by passive techniques, such as mechanical springs or rubber pads that are mounted to an object that vibrates. Here’s a great example of passive isolation that almost everyone can understand – when riding a bicycle, vibrations from the tires pass through the bicycle wheels to the handlebars, causing your arms and hands to vibrate and shake. Cushioned cycling gloves tend to “isolate” your hands from the handlebars, preventing your hands and arms from getting injured or damaged.

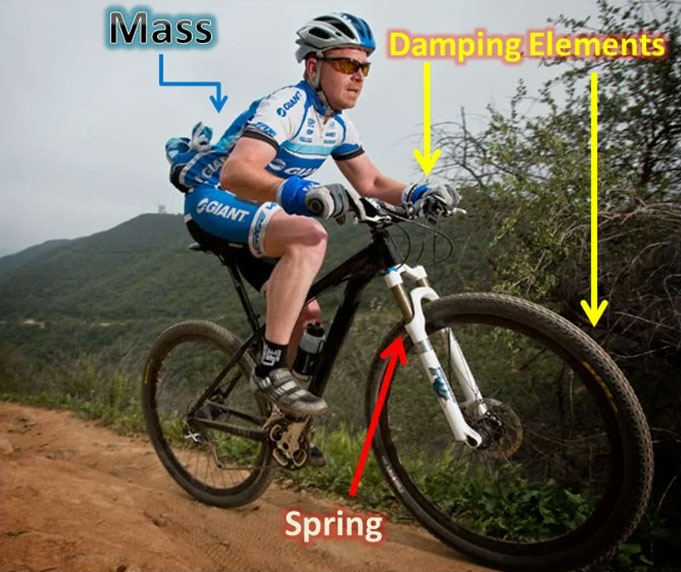

Usually, a passive isolation system contains a mass, a spring, and damping elements. In terms of a bicycle – the mass would be a human body seated on the bicycle, the spring would be the shock system built into the front fork of the bicycle, and the damping elements would be the tires, wheels, and handlebar grips. The spring and mass stiffness determine the natural frequency of the system, and the damping causes dissipation and has a secondary effect on the system’s frequency. The end isolation is attained primarily by maintaining the proper relationship between the disturbing frequency and the system’s natural frequency. There is no “absolute best isolation system,” and modifications and alterations should be made to increase efficiency depending on the application, frequency, direction, and strength of the vibrations.

Passive isolation is more commonly used because it operates in both directions.

What Does Passive Isolation Mean?

Passive isolation operates in both directions, which means that the system isolates the mass from the originating vibrations in the support while at the same time also isolating the support from the originating vibrations in the mass. A common challenge is having large appliances such as washers, pumps, and generators causing unwanted vibrations in the building. These machines are often isolated from the floor to reduce the vibration. However, since there are so many sources of vibration throughout the building, it is often impossible to isolate every source of the resulting vibration. When this happens, it is usually more efficient to isolate each fragile or sensitive instrument from the floor rather than isolating the original machine. Depending on your application, it is sometimes even necessary to implement both approaches by isolating both the original vibrating machine and also the sensitive instruments throughout your facility.

Active Vibration Isolation

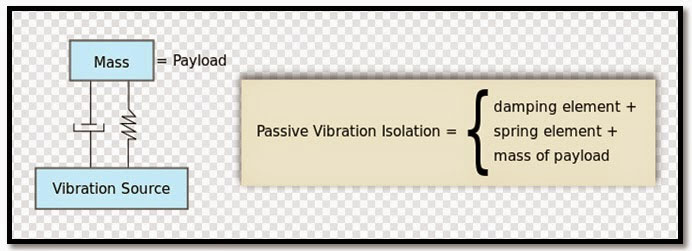

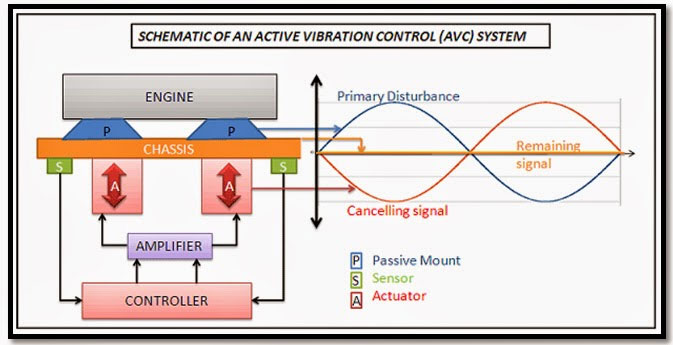

Unlike passive techniques, active vibration isolation systems require more effort and moving parts to create a working system. With active isolation systems, a feedback circuit controls the vibration isolation. The feedback circuit consists of a sensor, controller, electromagnetic transducer, mass, spring, and damper. To better understand the process, let’s explain the components of active vibration isolation.

The sensor typically used is an accelerometer, which is a device that measures proper acceleration, also known as “g-force.” A controller, generally a computer chip or stand-alone device that engages with a peripheral device, acts as the brain during active vibration isolation. The controller manages the shock isolation process and all of the associated moving parts. An electromagnetic transducer is a device that is responsible for controlling the vibration isolation system. It is operated by some sort of energy (electric current, hydraulic fluid, pressure, etc.) and then converts that energy into movement within the system.

In most scenarios, an active isolation system is used in conjunction with a passive isolation system. An accelerometer is attached to a stationary object that includes the passive vibration isolators. The accelerometer can detect a vibration transmitted from the isolators. A controller then analyses the frequency and amplitude of the vibration and outputs a feedback signal. An electromagnetic transducer receives the feedback signal and creates a force that cancels out the vibration.

The two main advantages of active vibration isolation systems are the increased stiffness and the ability to isolate low-frequency vibrations. With this type of comprehensive system, vibrations are considerably suppressed and controlled considerably more effectively than with ordinary damping practices.

Active isolation systems are used for applications in which structures smaller than a micrometer have to be produced and measured in a very accurate manner. Active isolation systems are usually used for medical systems, lithography, metrology, and photonics. The semiconductor industry also relies heavily on active isolation systems – during microchip production, the smallest chips today are below 20 nanometers, so the machines that produce and check the chips have to oscillate, or vibrate, much less than previous production.

To find more about vibration isolation systems, visit our Elastomeric Solutions page.